How to Build Your Own Speakers: Step-by-Step DIY Tech

It was back in 1924 that a couple of researchers from General Electric, Chester Rice and Edward Kellogg, patented what remains the basic design for virtually all the world's loudspeakers. In the 84 years since, engineers and enthusiasts have invested a lot of thought and energy in the refinement of Rice and Kellogg's concept, creating a valuable knowledge base for the do-it-yourself crowd.

I should know--I recently built the speakers pictured here, and in the process I learned quite a bit about the art and science of a good speaker.

At its core a loudspeaker is a surprisingly simple device. The key elements are the drivers, crossovers and the cabinet. The cone or dome drivers are transducers that transform the electrical signal into the physical movement of air (i.e., sound). Crossovers act as an electrical filter to split the signal and direct the portions of the audio-frequency range to the drivers best equipped to handle them. But coaxing rich and beautiful sound out of these elements requires a bit of harmonic alchemy. Every decision you make--from the combination of drivers and crossovers to the material you use to build the cabinet--influences the performance and character of your speakers.

Hardcore speaker hobbyists take delight in figuring all this out for themselves, designing and building the crossovers and enclosures from scratch to see what comes out. If that's your leaning, Parts Express is a well-stocked and reliable source for speaker builders and a good place to start.

But if that's too hit-or-miss, you can buy a speaker kit that comes with all the components, plus either a preconstructed cabinet or drawings to build your own. For this project, I opted for one of these hybrid kits, from North Creek Music Systems in Old Forge, N.Y. This little firm is run by George Short, a speaker engineer whose kits use his own driver and crossover designs but require you to buy cabinets elsewhere, or build them using the provided detailed woodworking plans. The benefit is that someone with know-how and good ears has gone through the time-consuming and costly process of "voicing" the speaker--engineering, auditioning and then re-engineering it until the desired sound is achieved.

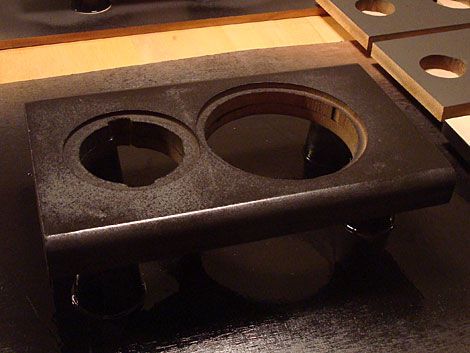

My own speaker-building ambitions were no grander than to have a little fun, learn a bit and come out with a pair of bookshelf speakers I could put in my home office. I selected North Creek's Okara II "Ikemo" kit, a ported design that delivers decent bass (down to about 60 Hz) from a small 0.25-cu.-ft. cabinet measuring 12 1/2 x 7 1/2 x 9 5/8 in. Its 5 1/2-in. woofer has a lightweight pressed-fiber cone coated with polypropylene, and the tweeter is a 1-in. silk dome. Silk is a material favored by many audiophiles for delivering superb midrange- and high-frequency detail without sounding bright or hard, the way some metal domes can.

The kit costs $369 for the pair and comes with everything except lumber and wood glue: drivers, crossovers, port tubes, acoustic stuffing and gaskets, the terminal cup for hooking up the wires from your amp and miscellaneous hardware. The simple crossovers--one each for the woofer and tweeter in each speaker--come with the coils, capacitors and resistors hard-wired on perforated breadboards. That saves some work, but these still must be mounted in the cabinets and wired to the drivers.

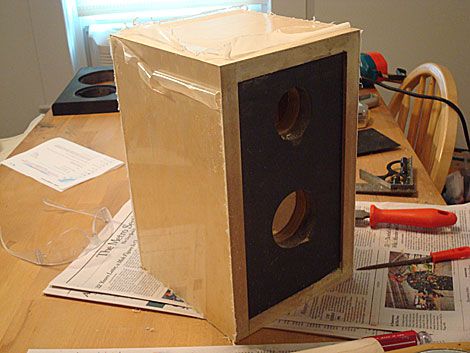

Building the cabinet was the most time-consuming part of the project, but it allowed me to customize the look of my speakers. Initially, I intended to build the cabinet from solid hardwood, but North Creek's plans recommend a combination of 3/4-in. medium-density fiberboard (MDF) backed with a layer of 3/4-in. birch plywood on the front fascia and back pieces. It turns out that MDF is not only cheaper, easier to mill and less susceptible to warping and shifting than hardwood, but the difference in densities of the MDF and plywood also reduces cabinet vibrations when you layer them together. To add rigidity, there is a plywood crossbrace running internally across the width of the box.

I painted the fascia and back MDF panels matte black and veneered the top, bottom and sides to effect the look of a hardwood finish. By scouting the Web I found an outstanding Italian-made composite veneer called Alpiwood, distributed by Brookside Veneers in Cranbury, N.J. It's an environmentally responsible material made from plantation-grown poplar that's been dyed and grained to match about 30 different common and exotic hardwoods, and it even comes prefinished with a polyurethane coating. The bird's-eye maple I chose has a tough laminate substrate and ships with a plastic sheet adhered to the finish to protect it during installation. You peel off the sheet after you've cut and applied the veneer--the stunning result is hard to distinguish from real finished hardwood.

One other tip: Invest in a Jasper circle-cutting jig for the driver, port and terminal-cup holes. The jig (model 400, partsexpress.com) is a legendary speaker-building tool that gets screwed to the base of the router to make perfect circle cuts that would otherwise be manually jigsawed. It costs $27 and is worth every penny.

After assembling the cabinet, I used construction adhesive to mount the tweeter and woofer crossovers inside the cabinet to the back and bottom walls, respectively. There's an odd bit of business in the kit's instructions about filling the rear-firing port tube with several dozen plastic straws that confused me at first, but a call to North Creek revealed that the straws help fine-tune the speaker's low-end bass limit. Then I connected the wires from the crossovers to the drivers on one end and the terminal cup on the other. And, finally, the woofers, tweeters, terminal cup and rear-firing port tube were glued and screwed into place.

After spending less than $100 for wood, on top of the cost of the kit, I ended up with a high-performance system that sounded better than most $500 speaker pairs I've heard. Though bass was limited by the speaker's size, it was well-balanced, without the inaccurate, bloated sound you hear with cheap speakers purposely pumped up to overcompensate for their size. The midrange was musical and open, free of the harsh colorations you sometimes hear on vocals. High frequencies were nicely detailed, if a little laid back, and held together well at moderately high volumes for such a compact speaker.

For me, speaker building was a rewarding mix of woodworking and electronics--beautiful and functional at the same time. When friends and family come to visit and comment on the rich, bird's-eye maple cabinets, I'll tell them, "Yeah, I built those. But just listen ..."

The Jasper Circle Jig: A lifesaver!

Drilling guide holes for the jig's pivot pin.

Left: The jig goes for a spin atop a fascia panel. Right: A milled fascia piece showing holes plus countersinks. Note the dog-ears manually rasped into the tweeter hole to account for its side-mounted terminals. This was not mentioned in the instructions, which seemed to have been written long ago, and on several occasions didn't fully account for the peculiarities of the included parts. But half the fun is wingin' it.

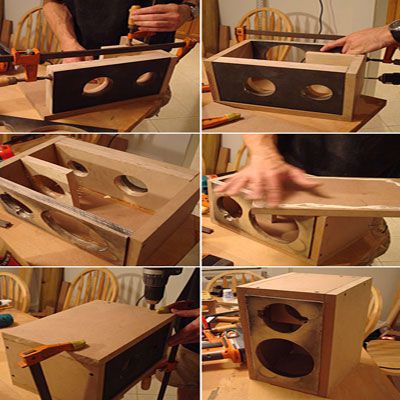

Gluing and clamping the fascia.

Matte black spray paint for the fascia and black panels. In the end, getting an acceptably smooth finish required two coats of spray primer and a couple of coats of black enamel.

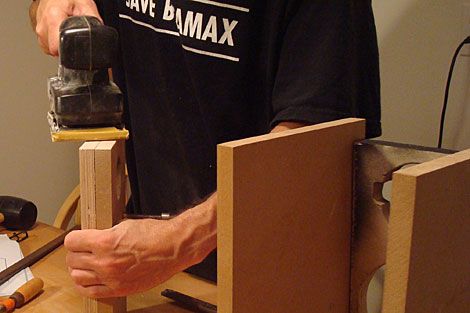

Prep for assembly includes dry-fitting all the pieces and tweaking panels as needed for a perfect fit.

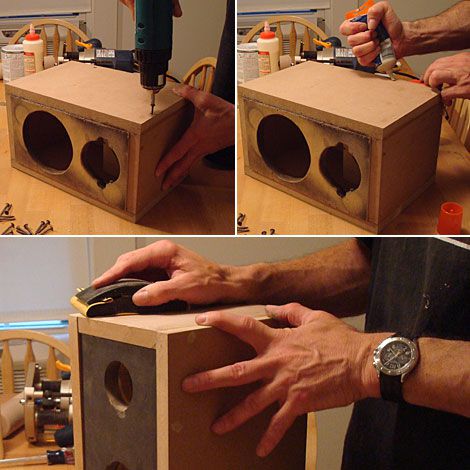

For efficiency, assembly involves gluing and clamping the panels together with butt joints, then putting in temporary drywall screws to keep the glue joints tight while you remove the clamps and move on to the next panel. After the glue drys, the screws come out and the holes and countersinks are filled with wood putty.

Box assembly.

Screw removal and puttying of the screw holes in preparation for veneering. The putty is sanded flat once dry.

Top: Rough-cutting veneer and its thick laminate substrate with multiple passes of a sharp utility knife.Bottom: Contact cement is applied to both surfaces and the veneer carefully aligned and layed down. A new rolling pin with an unblemished surface was used to apply maximum pressure rather than the small rubber J-roller commonly used for veneer; the veneer's protective sheathing made it possible to do this without damaging the finish.

The veneered box, still with protective plastic sheathing on the veneer, after all sides are completed. In between panels, the overhanging edges of the veneer were carefully trimmed with a router equipped with a flush-trim bit.

Gluing the fascia to the front inner-brace, and the finished cabinet ready for components.

Components and completed cabinet ready for final assembly.

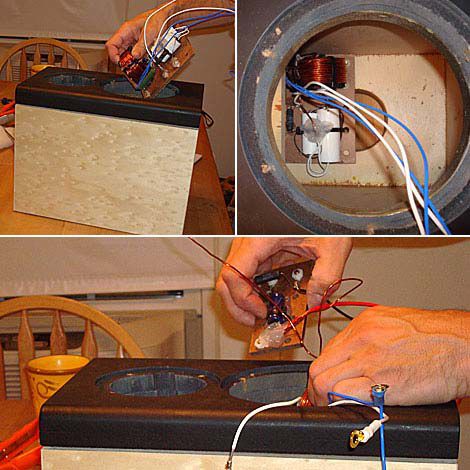

Dry positioning the crossovers before cementing to the cabinet walls.

Stuffing the port tube with plastic straws cut to 3-in length.

Top: Installing the port tube: applying rubber gasket sealing tape, drilling holes in the outer flange, and mounting.Bottom: Once the tube is in, construction cement is applied to the tweeter crossover through the terminal cup hole. Once dry, the speaker is flipped over and cement is applied to the woofer crossover through the woofer hole.

Top: The crossovers cemented in final position as viewed through the woofer hole.Bottom:Crossover input wires are fed through the terminal cup hole

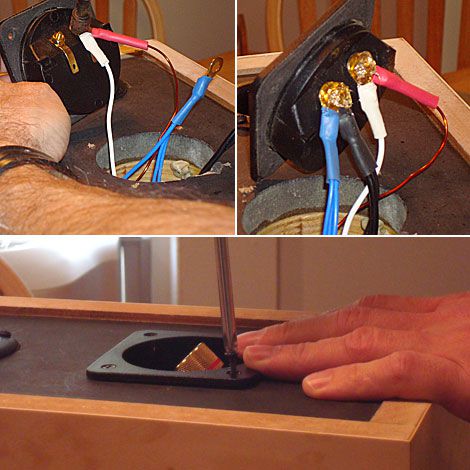

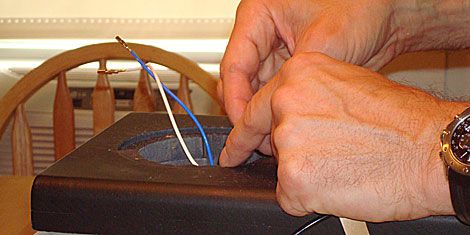

Connecting the crossover input wires to the speaker terminals with a nutdriver, then mounting the cup.

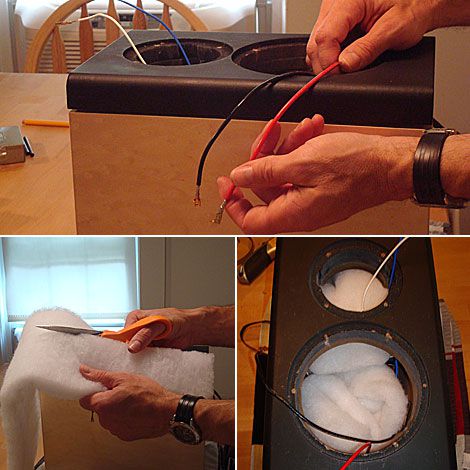

Top: Wires for the drivers are fed through the fascia holes.Bottom: Acoustic stuffing is cut and placed behind the driver holes.

Gasket tape is applied to both cutouts before mounting the drivers

The crimped crossover wires are connected to the drivers and the drivers are screwed down.

Done!